Schlupfbrüter MG1150H ECO

| Eggs Capacity | Hatcher |

| Hen - Duck - Mallard | 1152 |

| Pheasant | 1568 |

| Red legs | 2016 |

| Partridge - Quail | 2720 |

| Turkey | 800 |

| Goose | 448 |

| Technical data | ||

| Power Supply | V/Hz | 220-240 / 50-60 |

| Power Consumption | Watt. | 650 |

| Sizes | mm | 920x990x1420H |

| Net Weight | Kg | 140 |

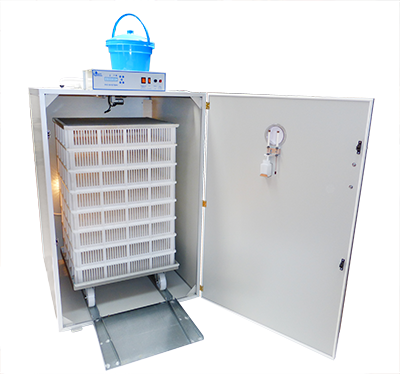

The model hatcher MG1150H ECO is the intermediate model of the ECO profesional hatchers series by air-ventilated, it has a movable trolley with 8 overlapping baskets and it is combined to incubators only setter without hatching compartment like model MG2500 S in order to have a professional approach by scheduled multistage loading which allows to obtain the best hatching performances.

This incubator model has been recently conceived and manufactured to meet the needs of people interested in starting a professional incubation project, without high capital investment. MG 1150 H ECO model hatcher combines a good capacity for eggs with a set of innovative systems allowing the user to work safely, fully complying with needs of small breeding farms. Thanks to high-quality manufacturing materials, this hatchery associates long duration with performance applicable to a professional machine.

• The structure consists of special walls made of prepainted galvanized sheet thermal panels, with 20-mm polystyrene insulation, ensuring perfect isolation and machine solidity

• The electronic control unit with backlit LCD allows managing – with a very easy usage – the full range of temperature and humidity.

•Temperature is read through °F precision thermometer and a wet-bulb hygrometer provides for an accurate reading of humidity percentage inside the incubator.

• A port-holes on the door provides for a perfect view inside the incubator and the internal light allows an easy inspections of the eggs .

• The machine is equipped with one self-cooling bearing professional fan and a special device to adjust ventilation intensity. The suitable air exchange followed by carbon dioxide exhaustion is through proper ventilation holes.

• A visual and acoustic alarm warns temperature abnormalities and stops heating when the maximum temperature limit set up by the user is reached.

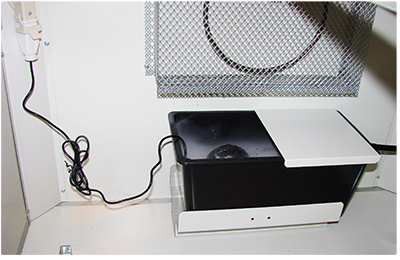

• Humidification is performed through covered tanks with constant level automatic water flow (automatic humidification is available upon request with digital adjustment and further reading through hygrostat).

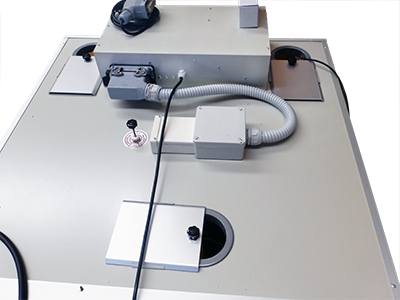

•Electro-mechanical thermostat independent of main control panel allows restoring machine main functions in case of malfunction to the control panel.

New “Evo Plus” Control Board

8 preset programs for each poultry species:

HEN, DUCK, GOOSE, QUAIL, PHEASANT, PARTRIDGE, TURKEY, GUINEA FOWL

CUSTOM program: for customizing incubation parameters

GERMINATION program: LED light on/off management timings for germination and plants growth

HATCHING program

- 4” TFT LCD color graphic display

- Extremely performing microprocessor for the highest accuracy in temperature and humidity management

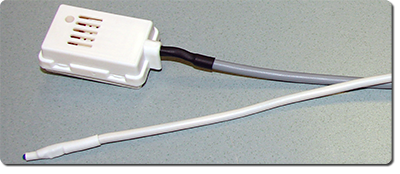

- New professional self-calibrating T/H sensor with top accuracy / temp. ± 0.1°C and humidity ±1.5%RH

- ON/OFF temperature management mode

- °C/°F immediate conversion setting

- Calendar : Incubation day counter and hatching cycle start warning

- Double incubation temperature program

- Temperature time bands program

- Egg turning program up to 4 intervals

- High temperature audible alarm

- Language setting: Italian/English

Optional function: Electric cooling (Clima Version)

OPTION: additional temperature sensor for external temperature display (room where the incubator is positioned)

OPTION: expansion for remote (plug-in WiFi module) viewing and control by a mobile phone

| DOUBLE T/H PROBE: Humidity and temperature sensors inside the machine are completely separated and disconnected to maximize reading accuracy and reliability. | Outside reserve water plastic tank | |

|

|

|

| Internal humidity water basin with constant water level + cover | Humidifier electric connection | |

|

|

|

| Ultrasounds humidifier by 1 membrane | Air Exchange shutters | |

|

|

|

| Electro-mechanical thermostat of maximum temperature alarm + emergency cable to restore machine main functions in case of malfunction to the control panel | Thermo-hygrometer kit for temperature and humidity values reading | |

|

|

|

| Movable trolley with overlapping hatching perforated plastic baskets with wire mesh cover | Self-cooling bearing professional fan | |

|

|

|

| External control panel | ||

|

||

The safety of electric components fully complies with EEC standards and the control panel outside the hatcher helps preventing any problem with electric components arising from humidity and condensate.